Background:

Customer's original design: NdFeB disc of D 1"x 1/8", N42

Application: holding

Force required: 17 lbs

Our suggestion:

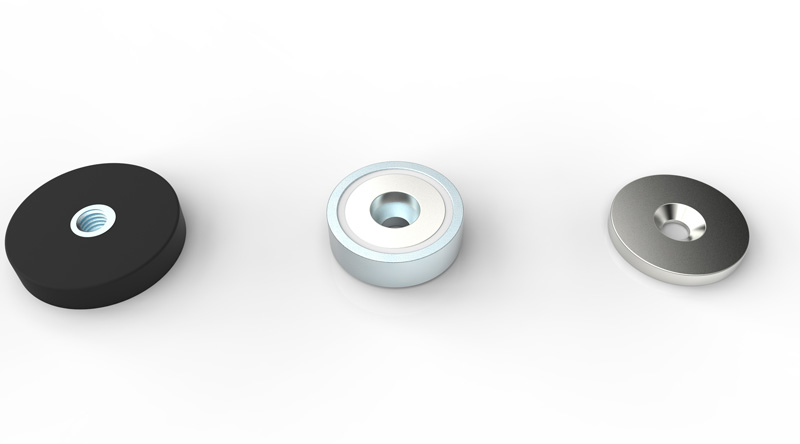

1) China NdFeB pot magnet with screw hole, overall size D25x8mm

2) Rubber coated magnet with screw hole, overall size D31x6mm

Comparison

Price: NdFeB disc > rubber coated magnet > pot magnet

Force: pot magnet (36 lbs) > rubber coated magnet (20 lbs) > NdFeB disc (17 lbs)

Anti-corrosion: rubber coated magnet > pot magnet > NdFeB disc

Anti-scratch: rubber coated magnet > pot magnet, NdFeB disc

Anti-risk ability against NdFeB price increase: pot magnet > rubber coated magnet >NdFeB disc

Final decision: rubber coated magnets to replace NdFeB disc in original design

From above comparison, it is obvious that rubber coated magnet beats others in its anti-corrosion and anti-scratch properties. Besides, even though it does not produce the highest force, it falls in acceptable range for the customer. When these pros are added up, it makes rubber coated magnet stand out from others with its great value vs price performance.

The other important feature of our products that gives the customer high motivation to change is the anti-risk ability against NdFeB price increase:

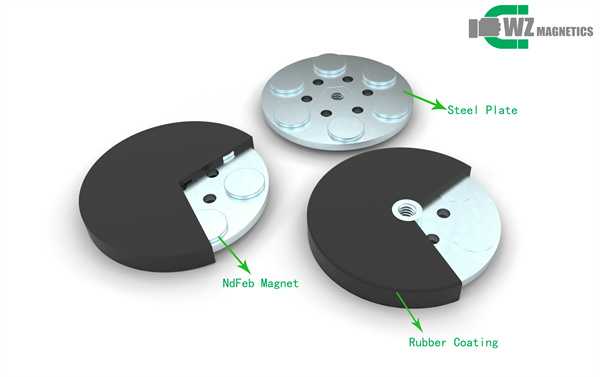

To get the same force, NdFeB magnet used in either pot magnet or rubber coated magnet is much less than using a whole piece of NdFeB magnet.

Diluted by other material such as rubber or steel, NdFeB is not that dominant in the cost composition of either pot magnet or rubber coated magnet, with which the price curve of these magnetic assemblies is milder over the time than that of NdFeB magnet.

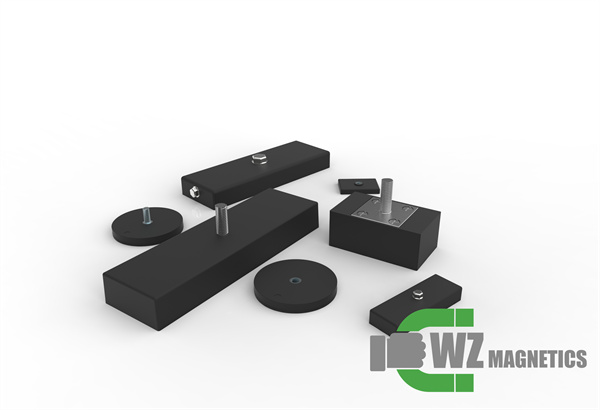

Types and Advantages of Rubber Coated MagnetsDecember 27, 2021Rubber coated magnets, also known as waterproof magnets, are one of the most commonly used tool magnets. In this article, let's learn about the types and advantages of rubber coated magnets.1. Man...view

Types and Advantages of Rubber Coated MagnetsDecember 27, 2021Rubber coated magnets, also known as waterproof magnets, are one of the most commonly used tool magnets. In this article, let's learn about the types and advantages of rubber coated magnets.1. Man...view Why Rubber Coating Neodymium Pot Magnets are powerful and protective magnet assembliesOctober 11, 2022Rubber coating magnets are made from core Neodymium-iron-boron (NdFeB) magnet, combined with steel body and hard-wearing rubber coating. Rubber coating magnet is a perfect combination of powerful strength and protection.view

Why Rubber Coating Neodymium Pot Magnets are powerful and protective magnet assembliesOctober 11, 2022Rubber coating magnets are made from core Neodymium-iron-boron (NdFeB) magnet, combined with steel body and hard-wearing rubber coating. Rubber coating magnet is a perfect combination of powerful strength and protection.view The Most Concerned Question of Rubber Coated MagnetsJuly 26, 2021Rubber-coated magnets, due to their unique feature of protecting holding surfaces while producing great holding force, are so widely selected by customers for their holding application. Some of these ...view

The Most Concerned Question of Rubber Coated MagnetsJuly 26, 2021Rubber-coated magnets, due to their unique feature of protecting holding surfaces while producing great holding force, are so widely selected by customers for their holding application. Some of these ...view Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China