Magnetization results from the response of a material to an external magnetic field. Ferromagnetic and ferrimagnetic materials have strong magnetization in a magnetic field and can be magnetized to have magnetization in the absence of an external field, becoming a permanent magnet. Magnetization is not necessarily uniform within a material but may vary between different points. Magnetization also describes how a material responds to an applied magnetic field as well as the way the material changes the magnetic field, and can be used to calculate the forces that result from those interactions.

Demagnetization is the reduction or elimination of magnetization. One way to do this is to heat the magnet above its Curie temperature, where thermal fluctuations have enough energy to overcome exchange interactions, the source of ferromagnetic order, and destroy that order. Another way is to pull it out of an electric coil with alternating current running through it, giving rise to fields that oppose the magnetization.

One application of demagnetization is to eliminate unwanted magnetic fields. For example, magnetic fields can interfere with electronic devices such as cell phones or computers, and with machining by making cuttings cling to their parent.

Pot Magnet2020/04/21These simple-looking pot magnets generate even higher holding force than using just magnet without steel pot. We offer you different styles, you can select what you want.

Pot Magnet2020/04/21These simple-looking pot magnets generate even higher holding force than using just magnet without steel pot. We offer you different styles, you can select what you want. Rubber Coated Magnet2020/04/21Rubber coated magnets or rubberised magnets are best described by one concept, that is: rubber coated magnet is a perfect combination of force and protection. Rubber covered magnets are actually one extension of pot magnets using the same working principle, but the rubber coating has greatly broadened the application scope of rubber coated pot magnets. If you are looking for reliable rubber coated neodymium magnet suppliers, Weizhong magnetics can provide you with high quality rubber coated magnets with reasonable price, which are strong and waterproof, and satisfactory service.

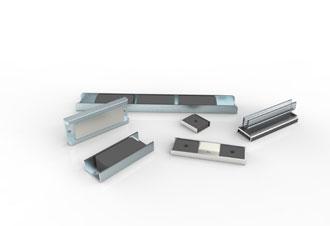

Rubber Coated Magnet2020/04/21Rubber coated magnets or rubberised magnets are best described by one concept, that is: rubber coated magnet is a perfect combination of force and protection. Rubber covered magnets are actually one extension of pot magnets using the same working principle, but the rubber coating has greatly broadened the application scope of rubber coated pot magnets. If you are looking for reliable rubber coated neodymium magnet suppliers, Weizhong magnetics can provide you with high quality rubber coated magnets with reasonable price, which are strong and waterproof, and satisfactory service. Channel Magnet2020/04/21Use these channel magnets to facilitate your work, your life by, for example, holding license plate, hanging posters, holding kitchen knives etc.

Channel Magnet2020/04/21Use these channel magnets to facilitate your work, your life by, for example, holding license plate, hanging posters, holding kitchen knives etc.A neodymium magnet (also known as NdFeB, NIB or Neo magnet) is the most widely used type of rare-earth magnet. It is a permanent magnet made from an alloy of neodymium, iron, and boron to form the Nd2Fe14B tetragonal crystalline structure. Developed independently in 1984 by General Motors and Sumitomo Special Metals, neodymium magnets are the strongest type of permanent magnet available commercially. Because of different manufacturing processes, they are divided into two subcategories, namely sintered NdFeB magnets and bonded NdFeB magnets. They have replaced other types of magnets in many applications in modern products that require strong permanent magnets.

Neodymium magnets are graded according to their maximum energy product, which relates to the magnetic flux output per unit volume. Higher values indicate stronger magnets. For sintered NdFeB magnets, there is a widely recognized international classification. Their values range from 28 up to 52. The first letter N before the values is short for neodymium, meaning sintered NdFeB magnets. Letters following the values indicate intrinsic coercivity and maximum operating temperatures.

Sintered Nd2Fe14B tends to be vulnerable to corrosion, especially along grain boundaries of a sintered magnet. This type of corrosion can cause serious deterioration, including crumbling of a magnet into a powder of small magnetic particles, or spalling of a surface layer.

This vulnerability is addressed in many commercial products by adding a protective coating to prevent exposure to the atmosphere, such as the rubber coated magnets. Nickel plating or two-layered copper-nickel plating are the standard methods, although plating with other metals, or polymer and lacquer protective coatings, are also in use.

Pot Magnet2020/04/21These simple-looking pot magnets generate even higher holding force than using just magnet without steel pot. We offer you different styles, you can select what you want.

Pot Magnet2020/04/21These simple-looking pot magnets generate even higher holding force than using just magnet without steel pot. We offer you different styles, you can select what you want. Rubber Coated Magnet2020/04/21Rubber coated magnets or rubberised magnets are best described by one concept, that is: rubber coated magnet is a perfect combination of force and protection. Rubber covered magnets are actually one extension of pot magnets using the same working principle, but the rubber coating has greatly broadened the application scope of rubber coated pot magnets. If you are looking for reliable rubber coated neodymium magnet suppliers, Weizhong magnetics can provide you with high quality rubber coated magnets with reasonable price, which are strong and waterproof, and satisfactory service.

Rubber Coated Magnet2020/04/21Rubber coated magnets or rubberised magnets are best described by one concept, that is: rubber coated magnet is a perfect combination of force and protection. Rubber covered magnets are actually one extension of pot magnets using the same working principle, but the rubber coating has greatly broadened the application scope of rubber coated pot magnets. If you are looking for reliable rubber coated neodymium magnet suppliers, Weizhong magnetics can provide you with high quality rubber coated magnets with reasonable price, which are strong and waterproof, and satisfactory service. Deep Pot Magnet2020/04/21Different from other pot magnets at the first look, these deep pot magnets are actually designed, produced using the same principle.

Deep Pot Magnet2020/04/21Different from other pot magnets at the first look, these deep pot magnets are actually designed, produced using the same principle.Also called ferrite magnet. A ferrite is a ceramic material made by mixing and firing large proportions of iron(III) oxide (Fe2O3, rust) blended with small proportions of one or more additional metallic elements, such as barium, manganese, nickel, and zinc.They are electrically nonconductive, meaning that they are insulators, and ferrimagnetic, meaning they can easily be magnetized or attracted to a magnet.

Ferrite compounds are extremely low cost, being made of mostly rusted iron (iron oxide), and have excellent corrosion resistance. They are very stable and difficult to demagnetize and can be made with both high and low coercive forces. Yogoro Kato and Takeshi Takei of the Tokyo Institute of Technology synthesized the first ferrite compounds in 1930.

Pot Magnet2020/04/21These simple-looking pot magnets generate even higher holding force than using just magnet without steel pot. We offer you different styles, you can select what you want.

Pot Magnet2020/04/21These simple-looking pot magnets generate even higher holding force than using just magnet without steel pot. We offer you different styles, you can select what you want. Channel Magnet2020/04/21Use these channel magnets to facilitate your work, your life by, for example, holding license plate, hanging posters, holding kitchen knives etc.

Channel Magnet2020/04/21Use these channel magnets to facilitate your work, your life by, for example, holding license plate, hanging posters, holding kitchen knives etc. Office Magnet2020/04/21Office magnets from Weizhong are sturdily designed and carefully fabricated featuring smaller size (mostly), more colorful or shining finish, more decorative.

Office Magnet2020/04/21Office magnets from Weizhong are sturdily designed and carefully fabricated featuring smaller size (mostly), more colorful or shining finish, more decorative.1.Neodymium magnet: also known as NdFeB, strongest permanent magnet ever invented, made from neodymium, iron, boron and other metals. It features high magnetic energy and is widely used. With Nd, Fe being active metals and easy to have chemical reaction with water, air , neodymium magnet often comes with coating for corrosion prevention. NiCuNi coating, Zn coating, epoxy coating are normally used coatings.

2.Ceramic (ferrite) magnet: magnet made from iron oxides as main material. Comparing with rare earth magnet, ceramic (ferrite) magnet features lower magnetic energy, lower cost and better corrosion resistance ability.

3.Rare earth magnets: magnets made from rare earth elements. Representatives are neodymium magnet, SmCo magnet.

4.Magnetization: the process to magnetize a magnet so as to let it have magnetic field normally by using a winding coil with a sudden high voltage current going through, which creates a instantaneous high density magnetic field to magnetize.

5.Demagnetization: to eliminate magnetism of a magnet by using a coil that create an opposite magnetic field.

6.Magnetic assembly: simply put, it is a category of products that combines magnet with non-magnetic component according to certain optimized magnetic circuit design. Magnetic assembly features enhanced holding force and easier mounting.

7.Holding force: we test the holding force of magnetic assembly by attaching it on a 10mm thick steel sheet at room temperature and then pulling it slowly in vertical direction with the device that is sensitive enough to record the strength at the moment when magnetic assembly is separated from the steel sheet. This is to give you a reference where the actual holding force in real application could be different with the change of, for example, pulling direction, thickness of the surface etc.

8.Magnetic shielding: to block magnetic field by using shielding materials, normally metal sheet, so that the magnetic field is reduced greatly. This is mostly used in packing magnetic assemblies for air shipment.

9. A B glue: This is not a special brand name of glue --- just a simple mixture of two different glues proved to have fabulous performance when used in gluing magnet onto metal parts. This is what we use in producing most of our magnetic assemblies.

Pot Magnet2020/04/21These simple-looking pot magnets generate even higher holding force than using just magnet without steel pot. We offer you different styles, you can select what you want.

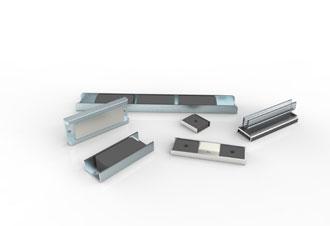

Pot Magnet2020/04/21These simple-looking pot magnets generate even higher holding force than using just magnet without steel pot. We offer you different styles, you can select what you want. Shuttering Magnet2020/04/21Shuttering magnets and other insert magnets consists of neodymium magnets with strong holding force. These revolutionary parts bring great ease and efficiency to precast.

Shuttering Magnet2020/04/21Shuttering magnets and other insert magnets consists of neodymium magnets with strong holding force. These revolutionary parts bring great ease and efficiency to precast. Rubber Coated Magnet2020/04/21Rubber coated magnets or rubberised magnets are best described by one concept, that is: rubber coated magnet is a perfect combination of force and protection. Rubber covered magnets are actually one extension of pot magnets using the same working principle, but the rubber coating has greatly broadened the application scope of rubber coated pot magnets. If you are looking for reliable rubber coated neodymium magnet suppliers, Weizhong magnetics can provide you with high quality rubber coated magnets with reasonable price, which are strong and waterproof, and satisfactory service.

Rubber Coated Magnet2020/04/21Rubber coated magnets or rubberised magnets are best described by one concept, that is: rubber coated magnet is a perfect combination of force and protection. Rubber covered magnets are actually one extension of pot magnets using the same working principle, but the rubber coating has greatly broadened the application scope of rubber coated pot magnets. If you are looking for reliable rubber coated neodymium magnet suppliers, Weizhong magnetics can provide you with high quality rubber coated magnets with reasonable price, which are strong and waterproof, and satisfactory service. Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China