Rubber coated magnets or rubberised magnets are best described by one concept, that is: rubber coated magnet is a perfect combination of force and protection. Rubber covered magnets are actually one extension of pot magnets using the same working principle, but the rubber coating has greatly broadened the application scope of rubber coated pot magnets. If you are looking for reliable rubber coated neodymium magnet suppliers, Weizhong magnetics can provide you with high quality rubber coated magnets with reasonable price, which are strong and waterproof, and satisfactory service.

It doesn't happen when you need to hold something on a nice, elegant surface, you do with your greatest tenderness not to leave any scratch on it and this is why rubber coated super magnet is invented. Rubber coating can effectively avoid direct contact of the surface with sharp, hard objects minimizing the cause of scratch.

Basically, you can use them anywhere you want as long as they hold. The uniqueness of its rubber coating makes them more suitable for delicate surface than other magnetic products. TPV has superior chemical stabilities but using it in places where it is too hot, too cold or corrosive may compromise its life. As one of the professional magnetic assembly suppliers, we have rubber-coated magnets for sale of good quality.

The material we use for rubber-coated magnets is TPV which features better durability than regular rubber due to its more stabilized chemical properties. You do not need to worry about its becoming hardened or peeling off in a long time.

What's more, odorlessness is another benefit, which differentiates TPV from regular rubber. TPV does not stain --- try to use them with your bare hand for a while and TPV won’t leave any black marks on your fingers.

It is true that rubber coating does not contribute to a better force, instead, it reduces the holding force of the part. However, by following some approaches you still get wanted force with these rubber-coated super magnets. Simply put, a rubber coating of even thickness and an optimized structure will promote the holding force, which is exactly what we are using with our rubber-coated neodymium magnets.

SLIM DESIGN WITH A STRONG HOLDING FORCE

The slim design of the rubber-coated magnet hardly adds to the height and is supplemented by a rubber sheath to guarantee scratch, and resistance and protect the contact surface. Our high-performance rubber-coated neodymium magnets boast a very strong holding force of up to 350 kgs. and the holding force is available within an ample temperature range between -40°C to +80°C.

OUTSTANDING ANTI-SLIP CHARACTERISTICS AND SCRATCH PROTECTION

The rubber material used is particularly soft, thus creating sufficient resistance and lending magnets a particularly high anti-slip resistance. As a result, the Contact surface for magnet adsorption is well protected from scratches and the magnet sheath copes perfectly even in tough weather conditions and low temperatures as well as when exposed to UV radiation.

GOOD WATERPROOF PERFORMANCE AND CORROSION- RESISTANCE

The Santoprene rubber material has very good chemical stability. what's more, The rubber coating provides complete isolation from outside air, for which the rubberized magnets also passed over 1000hrs salt spray test. Which has very good waterproof as well as Corrosion resistance.

VARIOUS COLOR & SHAPE OPTIONS

The colourful rubber-coated magnets with various shapes can cater to your various applications perfectly, especially for decoration, display and visual management. They are eye-catching and can help to pass important information in a simple and direct way.

MAGNET MOUNTING, NO DRILLING, NO ELECTRIC WELDING

Rubber Covered Magnet products have easy access to great flexibility and high efficiency. No Welding, No Drilling, Easy operation. You can easily mount or remove it quickly without damaging the construction.

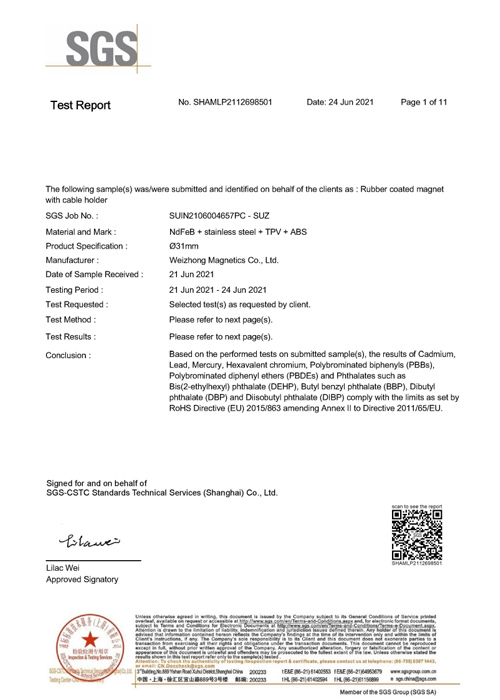

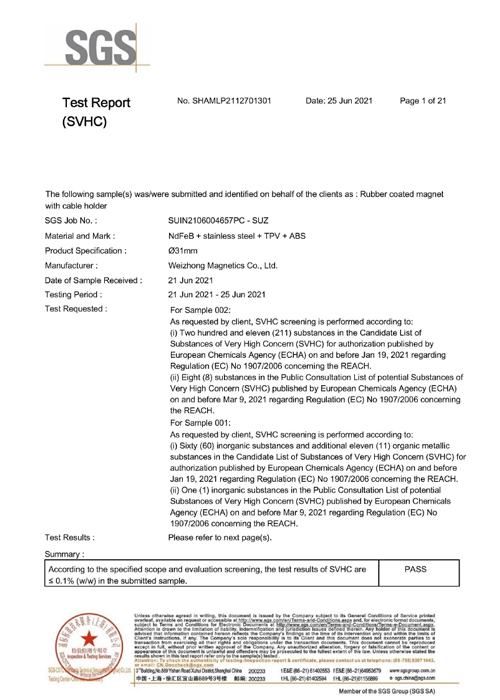

QUALITY RELIABLE

Our Rubber coated magnets are produced in line with RoHS and REACH Certified. What’s more, We are ISO 9001:2015 certified and we put every of our production steps, and quality control processes strictly in accordance with ISO requests. For which quality you can rely!

The rubber coating material we use features good chemical stability in harsh environments. The rubber coating layer also protects the magnets holding the surface from scratch.

Rubber coated Neodymium magnets give great durability and high friction. The rubber coating acts as a protection for the Neodymium Magnet inside against chipping and exposure to liquids. Rubber coated neodymium magnets are used in many holding applications especially when it is on a delicate surface.

Generally speaking, the fridge magnets you buy from gift or souvenir shops will have a flexible rubber or ferrite magnet on the back. Both types of magnets are great value for money while not as strong as neodymium magnets, they are more than strong enough to hold a lightweight item to a fridge. Both are flexible rubber and ferrite magnets are available with self-adhesive on one side and are great for making your own rubber fridge magnets.

A4: As the magnet is completely covered by rubber coating, rubber coated super magnets are water-proof as well as incredibly resistant to damage. Also the rubberised neodymium magnets is very durable and will not easily break like a normal magnet. Rubber coated neodymium magnets give great durability and high friction to keep them from slipping on surfaces.

Magnets can be machined. However, hard magnet materials – as opposed to the flexible or rubber covered magnets materials- are extremely difficult to machine. Magnets should be machined using diamond tools or soft grinding wheels, and in the un-magnetized state as far as possible. In general, it is best not to try and machine hard magnet materials unless you are familiar with these specialized machining techniques.

Our Rubber coated magnets are specially designed according to practical requirements in the specified industry, we are happy to develop waterproof magnets according to your specific application requirements.

Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China