Ever since very beginning we put quality at our first priority. Knowing that most of our customers are not capable of testing magnetic products and they totally rely on us, made us treat it even more strictly when it comes to quality. With implementation of our quality management system improved from practical operation, combined with the pursuit of even better performance, and by means of professional equipment/devices, our efforts in quality has made difference. Our customers think of us as a magnetic assembly manufacturer that has its principles, responsible and reliable. We often get customer's praise on the quality and are referred to new customers.

We are ISO 9001:2015 certified and we put every of our production steps, quality control processes strictly in accordance with ISO requests. What's more, we have invested computer-programmed automatic production lines with which we have minimized possible errors during operation and for large quantity orders, we can maintain consistently stabilized quality.

Companies in our supply chain have established solid cooperative relationship with us. We know each other really well and have built up a special working pattern. We always get qualified components on time to meet our production requirements. All our machines, tools are well maintained by a professional team. Calibration is carried out before every batch and data about machine performance are recorded to make sure they are in good condition. We have an effective training program for all the workers according to their own jobs. The whole production system is running efficiently. When un-expected urgent requirements happen, we can expand our capacity in a very short time due to the fact that we can get experienced part-time workers quickly to build up extra production lines. During our production, every step is traceable.

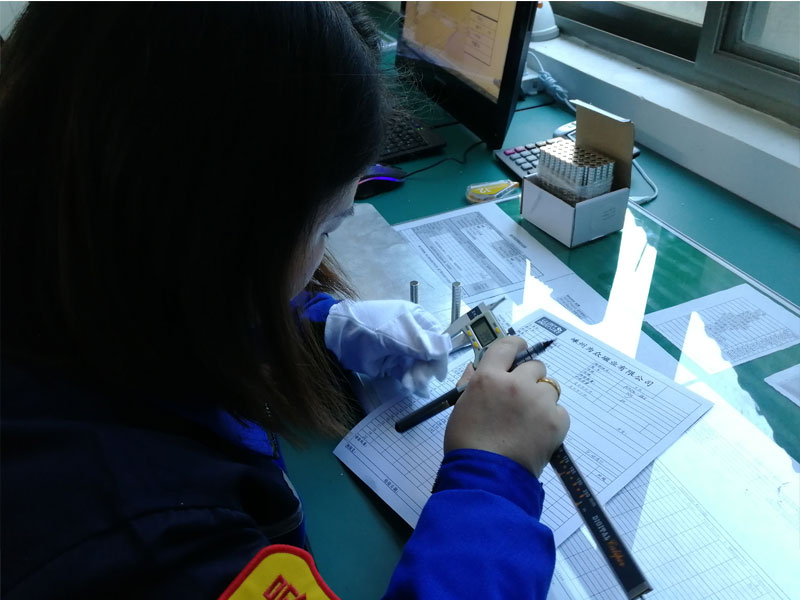

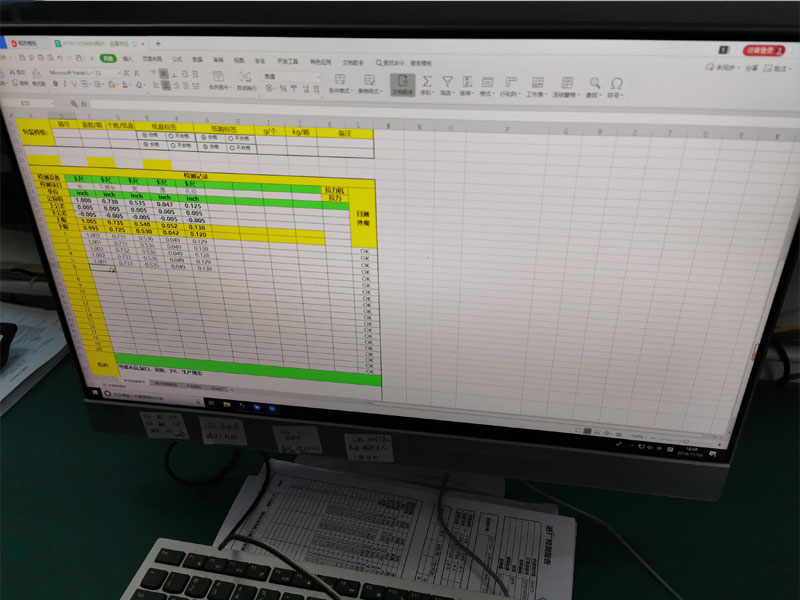

We have first article inspection before every batch production to make sure everything goes right.

Then our quality inspectors come to production lines on an hourly basis to randomly collect samples of semi-finished products for testing to make sure that the operation is done as instructed. Production will be stopped if anything wrong is observed from the testing and it can only be resumed until the issue is proved to be completely resolved.

When production is completed a final inspection based on AQL standard will be made and final judgment of ‘qualified’ or ‘not qualified’ will be given.

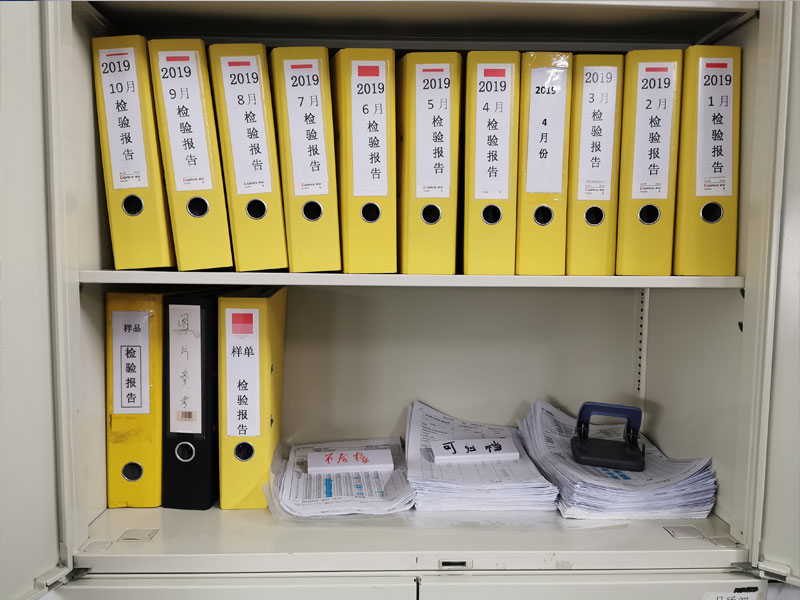

All data of inspections at different stages are recorded for possible reference in the future.

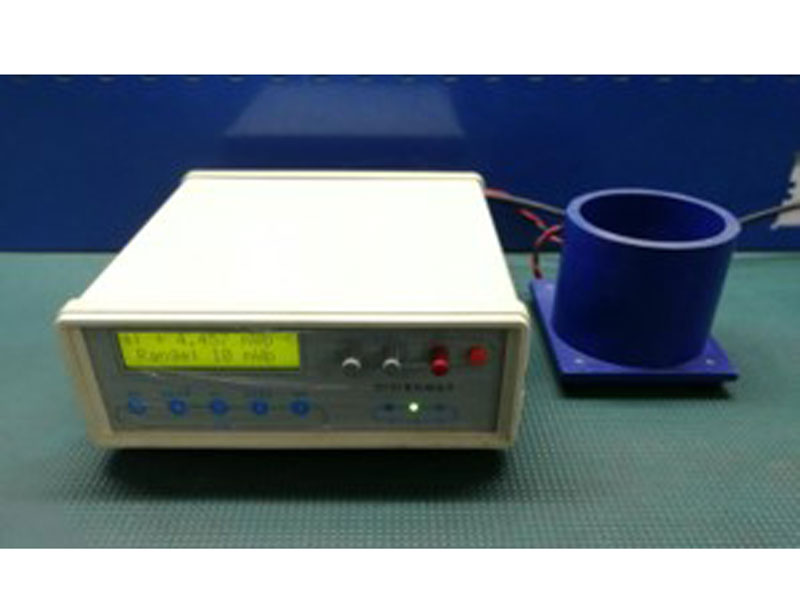

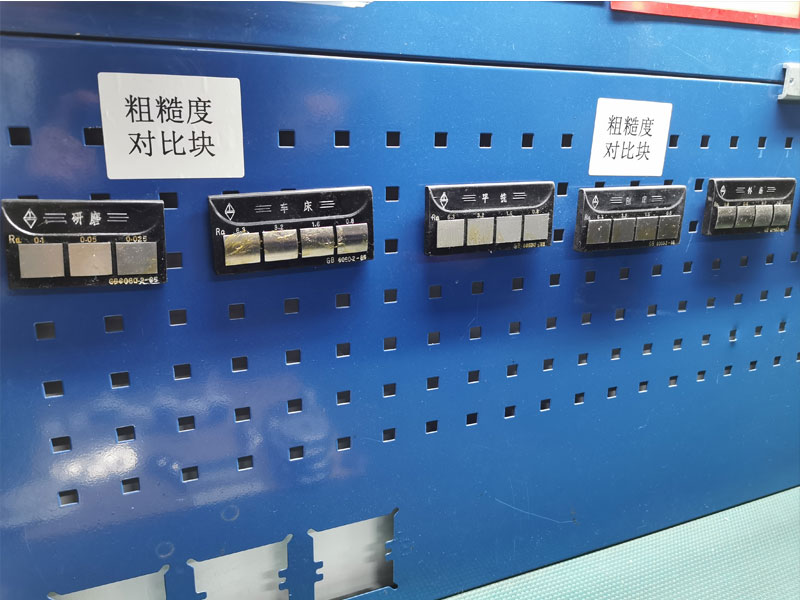

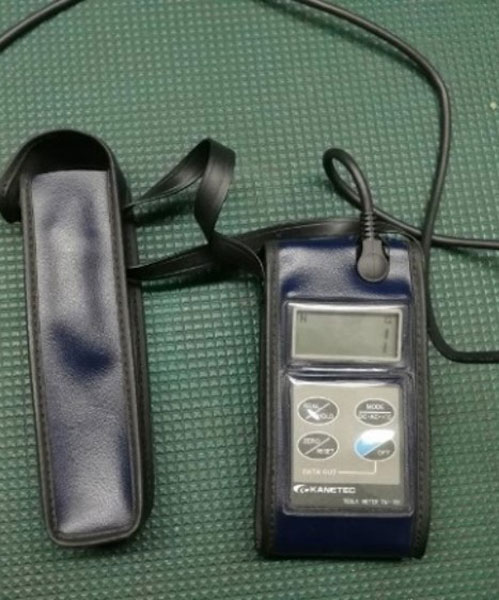

All devices, tools used for inspection, testing are well managed and they are calibrated by authorities at requested frequency.

Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China