Rubber coating magnets, also named waterproof magnets, are made from core Neodymium-iron-boron (NdFeB) magnet, combined with steel body and hard-wearing rubber coating. Rubber Coating Magnet is a perfect combination of powerful strength and protection.

Rubber coated ndfeb pot magnets use core disc neodymium magnets, one of the Rare-Earth Magnet, attached to a flat steel plate to get high magnetic field strength by changing the magnetic circuit, so that they can produce very high force on vertical surface by way of high utilization of magnetic energy.

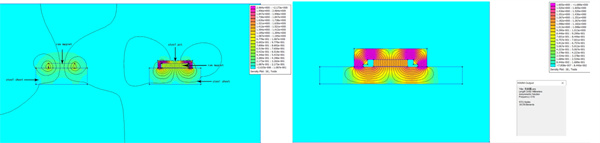

A simple illustration below shows that by using a steel plate to encase a piece of disc magnet we can get even higher magnetic field strength around the edge area. In practical use for holding applications, based on this principle, compared with using a piece of raw magnet we can get the same force with an even smaller magnet, with which the total cost can be significantly lowered.

Rubber coating pot magnet assemblies are coated with TPV rubber, a soft and durable rubber, which leaves neither scratches nor discoloration on delicate surfaces. Further, the protective rubber coating prevent core NdFeB pot magnets from corrosion or oxidation during long time and continuous using in outdoor environment. Moreover the high slip resistance is improved thanks to rubber coating.

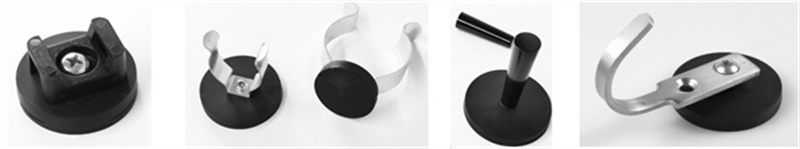

Those Heavy Duty Mounting Magnets with Rubber coating are actually one extension of Pot Magnet or cup magnet, pot magnet or cup magnet are covered with a steel cup, while rubber coating pot magnet are covered with a rubber layer outside a steel plate. Basically, as many kinds of pot magnets as there are of rubber coating pot magnets. We have developed the most diversity of rubber coating magnets, there are mainly including the following types:

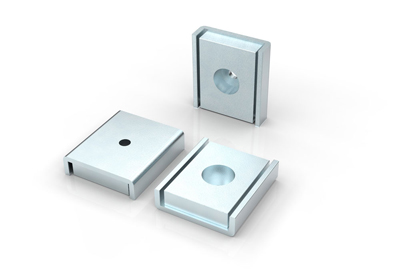

1) NdFeB rubber coated pot magnet with bore and counterbore

2) NdFeB rubber coated pot magnet with screw hole

3) NdFeB rubber coated pot magnet with screw bushing

4)NdFeB rubber coated magnet with internal thread

5)NdFeB rubber coated magnet with threaded stud

Not only including the common types in the markets. Other NdFeB rubber coating pot magnet with a plastic clips, hooks, or handles, or other accessories according to the special application.

Not only the usual black colors, different color particles combined could create virous colors. We have developed other available colors like as white, red, yellow, blue, orange. As a manufacturer, we are able to provide specified color upon your special requirments.

Rubber coating pot magnet assemblies have powerful magnetic strength and soft protective covers, so they can be regarded as one ideal solution for mounting or fixing applications such as hanging outdoor signage for display, installing lights or fixture to equipment maintenance, mounting camera or sensors on vehicles, without drilling and marking on gentle surface. Due to the powerful neodymium system, you can rest assured they will remain securely in place.

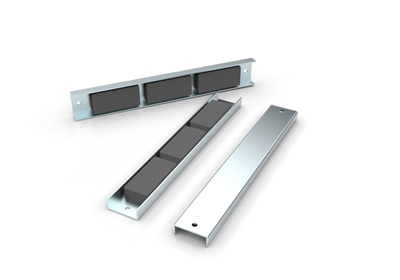

Ferrite Channel Magnet with Mounting Hole 8 InchApril 21, 2020This ferrite channel magnet can be fastened easily with screws and used, for example, in the workshop to hold tools.view

Ferrite Channel Magnet with Mounting Hole 8 InchApril 21, 2020This ferrite channel magnet can be fastened easily with screws and used, for example, in the workshop to hold tools.view NdFeB Memo Magnet with Plastic CaseApril 21, 2020These NdFeB memo magnets come in different colors, often packed in set.view

NdFeB Memo Magnet with Plastic CaseApril 21, 2020These NdFeB memo magnets come in different colors, often packed in set.view NdFeB Channel Magnet with Mounting Hole 1 InchApril 21, 2020NdFeB channel magnet has a through hole in the center and it can be fastened at places where the high holding force is needed.view

NdFeB Channel Magnet with Mounting Hole 1 InchApril 21, 2020NdFeB channel magnet has a through hole in the center and it can be fastened at places where the high holding force is needed.view Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China