Firm and reliable fixation is always needed in many places when making concrete precast parts. It has to be so stabilized that neither vibration, stirring or the bulk of the thick concrete mud can make it move and that’s how it is guaranteed that the final precast parts get their shape and size, meanwhile, built-in fittings such as anchors, wire boxes, tubes, etc are at the desired location.

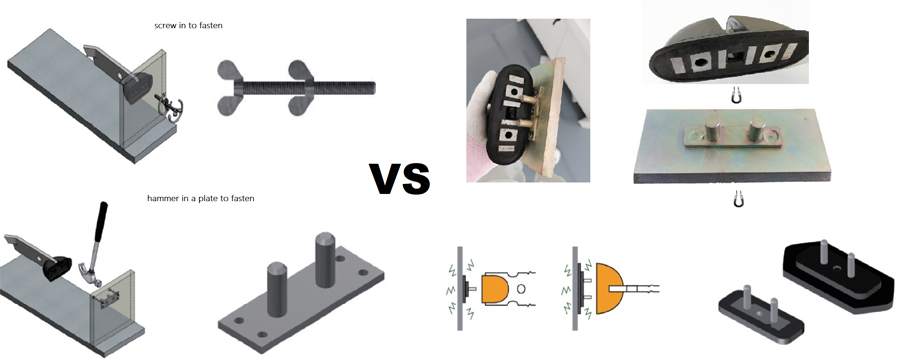

Traditional fixation solutions are mostly screws, pins that have a long history, while many precast plants are switching to magnetic solutions when they come to realize that this is going to make precast magnet much easier on the condition that the reliability of fixation remains.

The core principle is to fully use the attraction force generated by a magnetic field. Through careful design, these magnetic parts are efficient enough to concentrate the majority of magnetic energy on their holding face to generate a really strong force.

Simply put these magnetic parts at required places on a steel formwork and let the magnetic energy do their job - no need for the strength and time to screw or drill.

Besides, an experiment has shown that magnetic energy does not change for, at least, 30 years when used appropriately.

How much weight can precast formwork magnets lift2022/11/28When in production of precast concrete parts like a wall or a stair, the pouring of cement paste will produce strong push force against the side baffles and fitting accessories like lifting anchors, embedded wire box, etc. So strong precast formwork magnets are needed to fix the side baffles, lifting anchors, wire box, etc. in place firmly on the casting stable.

How much weight can precast formwork magnets lift2022/11/28When in production of precast concrete parts like a wall or a stair, the pouring of cement paste will produce strong push force against the side baffles and fitting accessories like lifting anchors, embedded wire box, etc. So strong precast formwork magnets are needed to fix the side baffles, lifting anchors, wire box, etc. in place firmly on the casting stable. Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China