Rubber coated magnets are composed of neodymium magnets or circular magnet sucking disc with a rubber coated protective layer. We generally use TPV rubber coating.

As one of the professional magnetic assemblies manufacturers, we can apply rubber coating to different shapes of magnets. The rubber coating can perfectly cover magnets or magnet assemblies that are standard round, lumpish, annular or countersunk hole shapes, or even more complex shapes. The rubber coating protects the magnet from corrosion and damage, so the rubber coated magnet is very durable.

The rubber coating is produced with injection molding machines. We need an injection mold of a specific size to evenly coat the rubber coating on the outer surface of the magnet. Normally, the rubber coating is black, but if you order the minimum order quantity, we can produce the rubber coated magnets with different colors.

The rubber coating is about 0.5 to 1 mm thick, which is much thicker than other coatings. Therefore, the actual size of the magnet inside the rubber coating is 2 mm smaller than that of the finished product.

Rubber coated neodymium magnets don't break as easily as regular magnets, so they can be used in wet and rusty areas, marine (seawater) environment, rough surface and other outdoor applications, which greatly broadens the application range of magnets.

The rubber coating protects both the magnet surface of and the magnet itself. If you want to use magnets on an injection-prone surface, such as a car surface, without leaving any marks and scratch damage, the rubber coated magnet is a suitable choice.

Weizhong Magnetics Co., Ltd. has been engaged in magnetic product assembly since 2010. With the accumulated experience, we have specialized knowledge in manufacturing and engineering design. We aim to continuously develop applicable magnetic components.

Up to now, Weizhong Magnetics Co., Ltd. has established the most complete production facilities, which pass the ISO 9001 certification. The facilities are used to produce magnetic components of various shapes and suction forces. The most popular products include slot magnets, magnetic hooks, rubber coated magnets, magnetic boxes, circular magnet cups, mounting magnets, magnet mounts, etc.

The goal of Weizhong Magnetics Co., Ltd. is to produce high-quality and high-performance products. The company is customer-oriented, so that our customers can fully trust our quality. We welcome customers around the world for visiting and consulting!

Rubber Coated Magnet2020/04/21Rubber coated magnets or rubberised magnets are best described by one concept, that is: rubber coated magnet is a perfect combination of force and protection. Rubber covered magnets are actually one extension of pot magnets using the same working principle, but the rubber coating has greatly broadened the application scope of rubber coated pot magnets. If you are looking for reliable rubber coated neodymium magnet suppliers, Weizhong magnetics can provide you with high quality rubber coated magnets with reasonable price, which are strong and waterproof, and satisfactory service.

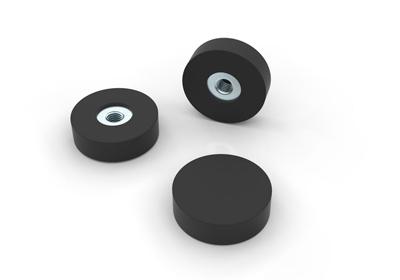

Rubber Coated Magnet2020/04/21Rubber coated magnets or rubberised magnets are best described by one concept, that is: rubber coated magnet is a perfect combination of force and protection. Rubber covered magnets are actually one extension of pot magnets using the same working principle, but the rubber coating has greatly broadened the application scope of rubber coated pot magnets. If you are looking for reliable rubber coated neodymium magnet suppliers, Weizhong magnetics can provide you with high quality rubber coated magnets with reasonable price, which are strong and waterproof, and satisfactory service. NdFeB Rubber Coated Magnet with Screw Hole2020/04/21This rubber coated magnet is made of neodymium magnet and has a screw hole making it easy to work together with a bolt.

NdFeB Rubber Coated Magnet with Screw Hole2020/04/21This rubber coated magnet is made of neodymium magnet and has a screw hole making it easy to work together with a bolt. NdFeB Rubber Coated Magnet with Bore and Counterbore2020/04/21This rubber coated NdFeB magnet has a center hole on one side and a countersunk hole on the other side.

NdFeB Rubber Coated Magnet with Bore and Counterbore2020/04/21This rubber coated NdFeB magnet has a center hole on one side and a countersunk hole on the other side. Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China