Magnetic assemblies are based on the original intention in various aspects, including preventing brittle magnets from breaking and greatly improving the magnetic field strength. The pot magnet is one of the excellent representative magnetic assemblies which embodies these two advantages.

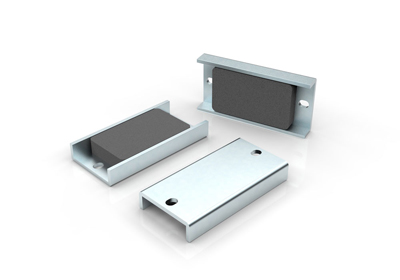

The pot magnet is composed of three parts: permanent magnet, steel shell and filler. NdFeB, samarium cobalt, ferrite and aluminum nickel and cobalt magnets are all suitable for pot magnets in steel shell. The steel shell, permanent magnet, and attraction part will form an integral magnetic circuit.

According to the processing technology of steel shell, the neodymium pot magnet can be divided into turning and stamping design. Different from stamping design, turning design does not require molding cost, and the product line is more abundant, especially for large-scale pot magnets. It should be noted that for the same size, turning design is usually more attractive than stamping design due to excellent machining accuracy.

The cost of a pot magnet can be reduced by reducing the grade of the magnet and optimizing the overall design while the suction of the product is not affected.

Low-cost magnets can be used in turning and stamping designs. The related structural optimization mainly focuses on the steel shell and the thickness reduction of the magnet. For the turning design, the size change of the steel shell is convenient because of its processing method.

As a professional magnetic assembly manufacturer, our Weizhong team suggests that you should provide us with detailed usage scenarios and requirements of attractions, and then we will provide you with reliable and economical solutions.

Ferrite Flat Pot Magnet Hook in Different ColorsApril 21, 2020These Ferrite pot magnets are often packed in sets of four, six with different colors, which is perfect for hanging or holding objects as decorative magnetic hooks.view

Ferrite Flat Pot Magnet Hook in Different ColorsApril 21, 2020These Ferrite pot magnets are often packed in sets of four, six with different colors, which is perfect for hanging or holding objects as decorative magnetic hooks.view Ferrite White Powder Coated Magnet with Swivel HookApril 21, 2020The central bolt, where the hook is mounted, is a rotating one that can turn 360°.view

Ferrite White Powder Coated Magnet with Swivel HookApril 21, 2020The central bolt, where the hook is mounted, is a rotating one that can turn 360°.view Ferrite Channel Magnet with Mounting Hole 3 InchApril 21, 2020This ferrite channel magnet has one mounting hole on each end and can be fastened easily with screws.view

Ferrite Channel Magnet with Mounting Hole 3 InchApril 21, 2020This ferrite channel magnet has one mounting hole on each end and can be fastened easily with screws.view Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China