We mainly use either vulcanization or injection molding to produce these rubberized magnets. We choose either of them depending on the product itself. These two production technique is quite different but they both make high performance rubber covered magnets.

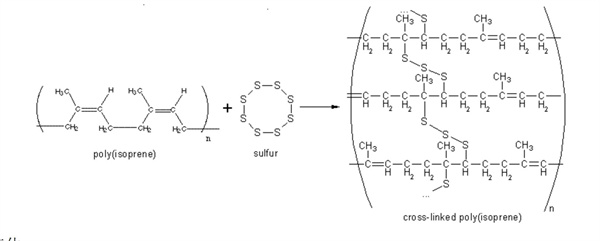

1. What is vulcanization

To put it short, vulcanization is a special process, after which the rubber shows much different mechanical and chemical features to be more suitable as a material for industrial products that require the rubber to be harder, more durable etc.

Natural rubber features great elasticity and unrecovered plastic strain with a very small outside force. This feature, in most cases, is related to its long linear polymer chain structure.

Vulcanization, in micro scale, is using a vulcanizing agent to form cross-links between the polymer chains to get 3-d network structure. As a result, the material becomes harder, more durable and also some other changes in the mechanical and chemical characteristics.

2. Which rubber-coated magnets are made by vulcanization?

Most of our big size square shape rubber coating magnets are made with vulcanization.

These rubber covered magnets are mostly used in highly corrosive environment with direct contact to water, UV, oil etc But with vulcanized rubber coating outside you do not need to worry about the harsh working condition.

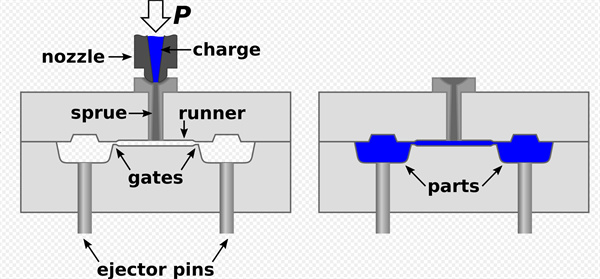

1. What is injection molding

It is to inject raw material into a mold cavity using pressure while the material is molten and then it cools down and hardens according to the shape of the cavity. Injection molding is a much quicker method comparing with vulcanization and is more likely to use automation in the process. With injection molding we can produce parts in various shapes, sizes. Another advantage of injection molding is that it produces parts with high accuracy.

2. Which rubber coating magnets are made by injection molding

All of our round shape rubber coated magnets are made with injection molding.

1. Difference

Vulcanization changes properties of the material to make it more suitable for challenging working environment. Injection molding does not change material's properties and it is just to form the shape of the parts, so the material used for injection molding makes difference in the performance of the final product.

2. Rubber Materials

We use TPV produced by Exxon Mobile in injection molding for our rubber coated magnet. TPV, with its superior mechanical and chemical characteristics makes our rubber covered magnets being outstanding in corrosion resistance, oil resistance and can be a great choice for uses in, for example, outdoor, off shore etc. And TPV is recycle material. While vulcanizing molding process uses NBR or EPDM rubber, NBR rubber features mostly oil resistance and EPDM rubber features mostly long-term aging.

3. Investment

The mold tooling cost of vulcanizing molding process is cheaper, while the mold cost of injection molding process is several times of vulcanization process.

4. Working effectivity

The working efficiency of injection molding process is much higher than that of vulcanization process.

5. Magnetisation

The high temperature in vulcanization molding process demagnetizes the magnet, so unmagnetized magnet need to be assembled and vulcanization molded and then magnetizing after rubberized. If it is impossible to magnetize after rubberized, then high temperature resistant magnet like NxxSH or NxxUH grade NdFeB has to be used to make sure the magnetic strength does not weaken or disappear during vulcanization. The injection molding process allows magnetized magnet assembled before rubberizing.

6. Which one to choose in production?

Injection molding is fast but has its limitation, for example, it can't process materials such as NBR, EPDM. But vulcanization can. So, there is no universal principle regarding which one to use to produce rubber coating magnets it is based on customer's requirement, material to be processed and a lot of practice.

NdFeB Magnetic Fixing Plate for Socket SystemApril 21, 2020These magnetic fixing plates are used to fix the sockets to steel formworks. We have diameters of 60mm, 74mm, and 90mm, pull-force from 50KGS, 100KGS to 120KGS with thread M12 toM36 on request.view

NdFeB Magnetic Fixing Plate for Socket SystemApril 21, 2020These magnetic fixing plates are used to fix the sockets to steel formworks. We have diameters of 60mm, 74mm, and 90mm, pull-force from 50KGS, 100KGS to 120KGS with thread M12 toM36 on request.view Ferrite Flat Pot Magnet with Rotating Metal HookApril 21, 2020The hook is not fixed in position but can rotate around the center offering great flexibility.view

Ferrite Flat Pot Magnet with Rotating Metal HookApril 21, 2020The hook is not fixed in position but can rotate around the center offering great flexibility.view NdFeB Channel Magnet with Mounting Hole 3 InchApril 21, 2020This NdFeB channel magnet has one mounting hole on each end and it can be fastened easily with screws.view

NdFeB Channel Magnet with Mounting Hole 3 InchApril 21, 2020This NdFeB channel magnet has one mounting hole on each end and it can be fastened easily with screws.view Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China