(1) NdFeB rubber coated magnets are usually sintered (namely powder metallurgy), which are hard and fragile, and cannot be punched. If you want to open the hole, you can stick the hole of the NdFeB rubber coated magnet with tape before the NdFeB magnet is sintered, that is, add a core to the die and take it out.

(2) Use hard alloy drill bits. But it is best to ask the magnet factory to process the NdFeB rubber coated magnets before use, but usually, very small holes are made by ultrasonic or laser.

(3) Electrical treatment seems impossible. In any case, rubber coated magnets cannot be treated with ordinary equipment, so as to prevent the NdFeB rubber coated magnets from being demagnetized. It is recommended to reserve holes at the beginning of the production of NdFeB rubber coated magnets.

(4) It is best to use NdFeB magnets, add water and use a bench drill to punch holes on the NdFeB rubber coated magnets.

The key is to reduce the speed, slow down the speed of the tool, and maintain the water level. Be cautious especially when operating it. If it is normal (black), you must be more careful. In a nutshell: turn slowly, advance slowly, add water often, and the drill bit must be sharpened.

(5) If you just punch holes on the NdFeB magnets, the electronic pulse is definitely applicable, and it is recommended to try it.

(6) The molded NdFeB rubber coated magnet is difficult to process, so please consider the method in advance and design it directly.

(7) The NdFeB rubber coated magnet adopts the method of vibration cutting.

The tool vibrates 30,000 times per second. It is especially used for cutting various brittle and hard materials, such as ceramic glass. There is also a kind of equipment, special graphite processing equipment, which will be used for magnet processing.

Manufacturers of NdFeB rubber-coated rare earth magnets usually use desktop drilling machines. This equipment mainly drills on NdFeB rubber-coated neodymium magnets (punching holes).

Of course, you can also try to punch a hole in the NdFeB rubber-coated magnets with a vibrating diamond grinding wheel bit. If it is magnetic, it must be demagnetized first. The NdFeB rubber-coated magnets are all formed by the method of compression moulding. If processing is required, only simple grinding is needed. Therefore, NdFeB rubber-coated magnets are mainly round and square.

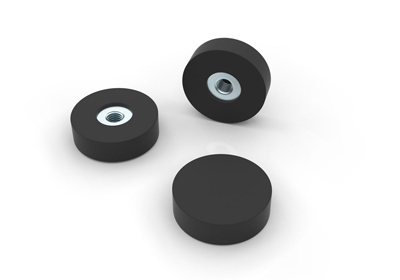

NdFeB Rubber Coated Magnet with Screw HoleApril 21, 2020This rubber coated magnet is made of neodymium magnet and has a screw hole making it easy to work together with a bolt.view

NdFeB Rubber Coated Magnet with Screw HoleApril 21, 2020This rubber coated magnet is made of neodymium magnet and has a screw hole making it easy to work together with a bolt.view NdFeB Deep Pot Magnet FlatApril 21, 2020These NdFeB deep pot magnets are cylindrical and flat, in which Neodymium magnets are placed centrally in the steel part.view

NdFeB Deep Pot Magnet FlatApril 21, 2020These NdFeB deep pot magnets are cylindrical and flat, in which Neodymium magnets are placed centrally in the steel part.view Round Magnetic Base with GripperApril 21, 2020Round Magnetic Base with Gripper has a wide gripper for holding post, banner, sign, find more applications here!view

Round Magnetic Base with GripperApril 21, 2020Round Magnetic Base with Gripper has a wide gripper for holding post, banner, sign, find more applications here!view Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China