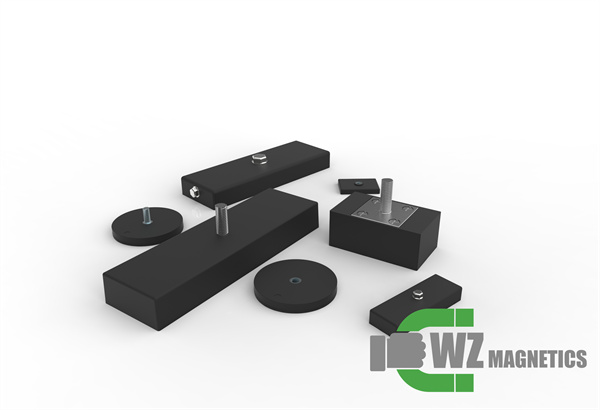

The rubber-coated magnet features strong friction force, great corrosion resistance, and good scratch protection with various colour options, which make it a really suitable choice in so many applications. A complete resume of this product might enrich your knowledge to help you make the quick and correct decisions in choosing among different magnetic products.

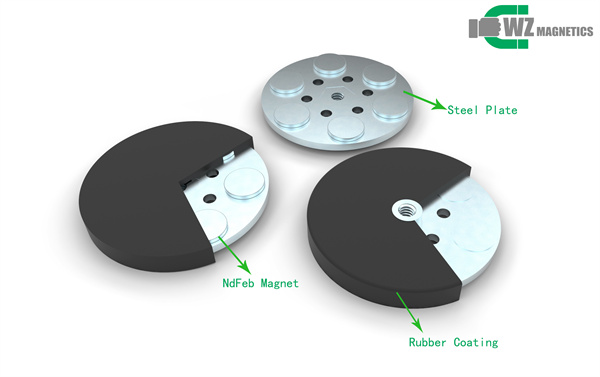

Rubber coated magnets can also be called rubber encased magnets, If you cut open the rubber coating you will find out that the core is a magnet assembly using NdFeB magnets with a well-designed magnetic circuit and this is how we get the force. Then, we put on the rubber cover by injection molding or vulcanization so that the rubber adheres tightly to the core to create corrosion resistance and shock protection.

To put it in a short and simple way, we put rubber on magnetic assemblies using a special technique to get a combination of magnetic force, protection and corrosion resistance in one solid product.

1 Strong Pull Force and Sliding Force

The well-designed magnet assembly inside guarantees high enough pull force in the vertical direction. The rubber coating outside increases the friction in the horizontal direction to produce a higher sliding force than other magnetic parts without rubber coating. As a result, these rubberized magnets can be used to hold objects either vertically, for example, from the ceiling, or horizontally, such as, on the wall.

2 Good Corrosion-Resistance

Neodymium used inside these rubber-coated magnets is the main reason that we get such high force but neodymium magnets are quite chemically active and are very much likely to react with CO2 and water in the air to be oxidized. Even with electric coatings, it is still risky to put NdFeB magnets in a highly rust-proof environment.

The rubber coating provides complete isolation from outside air so the neodymium magnets inside never have contact with either CO2 or water, and corrosion never happens.

The rubber material we use is TPV and this material has very good chemical stability. Our rubber-coated magnets using TPV have passed over 1000hrs salt spray tests.

3 Scratch Protection

The rubber coating outside is a much softer material than any metal. It is soft enough that no scratch is left even if it scrapes on the painted surface. You can use it, for example, on the car, or on the refrigerator as shown below. No scratch and no stain would be left on the surface.

4 Shock Protection

The rubber coating can also provide a buffer if you drop the magnet onto the floor. The NdFeB magnet inside is not that easy to break.

5 Colorful

In addition to being black or white, we have more options on colours so that you can pick them for decorative purposes or warning purposes etc.

Q: Does rubber coating affect magnetic force?

A: Yes, it does and we have already put it into consideration when we design the product. The force of the magnet assembly core is high enough for the final product to reach the rated force.

Q: Not every user is that accurate to hanging objects within rated force range and isn’t that dangerous?

A: Yes, this happens and it is dangerous. So, first of all, retailers or distributors need to get customers’ attention to the safety range according to the product’s force. We, as a manufacturer of these rubber-coated magnets, have put in some safety margin from 10% to 30% on these magnets, which means, for example, with a rubberized magnet of 10kg force it can actually reach 11kg or more.

Q: Does the magnet lose its force over time?

A: An experiment has proved that, if used in proper condition (especially used at an appropriate working temperature) irreversible magnetic loss would be less than 1% in 30 years.

NdFeB Magnetic Recess FormerApril 21, 2020These hemispherical magnetic recess formers are co-used with anchors. We have D60mm(50KGS) for 1.3t anchor, D74mm(100KGS) for 2.5t, D94mm(120KGS) for 5.0t and D118mm(190KGS) for 10ton anchor.view

NdFeB Magnetic Recess FormerApril 21, 2020These hemispherical magnetic recess formers are co-used with anchors. We have D60mm(50KGS) for 1.3t anchor, D74mm(100KGS) for 2.5t, D94mm(120KGS) for 5.0t and D118mm(190KGS) for 10ton anchor.view NdFeB Memo Magnet with Brushed FinishApril 21, 2020These NdFeB memo magnets are suitable for visual management and office presentation. With neodymium magnet inside they give enough high force to hold several paper.view

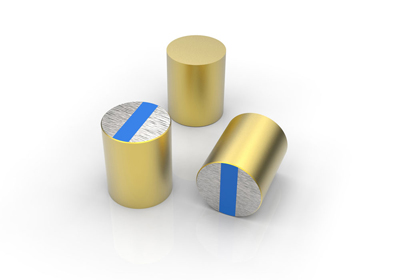

NdFeB Memo Magnet with Brushed FinishApril 21, 2020These NdFeB memo magnets are suitable for visual management and office presentation. With neodymium magnet inside they give enough high force to hold several paper.view NdFeB Deep Pot Magnet with Brass Body, Blue EpoxyApril 21, 2020This cylindrical NdFeB Deep Pot Magnet with Brass Body, Blue Epoxy features high holding power and small size. It is widely used for holding and lifting.view

NdFeB Deep Pot Magnet with Brass Body, Blue EpoxyApril 21, 2020This cylindrical NdFeB Deep Pot Magnet with Brass Body, Blue Epoxy features high holding power and small size. It is widely used for holding and lifting.view Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China