Rubber coated magnets are used in different working conditions and environments, Generally widely used for mounting or holding purposes, used for mounting lights, cameras, or fixtures to equipment repair, holding tools and organizing items in car surface, warehouses, workstations and outdoor areas etc.

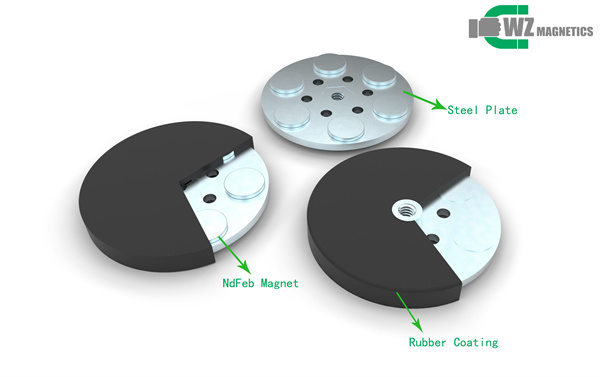

The surface of the rubber coated magnet is covered with synthetic rubber material, which not only has waterproof function, but also has very good damage resistance, unlike ordinary magnets that are easily broken. The overmolded magnet chuck is extremely durable, while the overmolded material enhances horizontal friction and prevents it from sliding on the mounting surface.

For applications that require long-term exposure to outdoor sunlight, corrosive gases and liquids, oil pollution, etc., you can find a suitable choice in our encapsulated magnet. According to the 12-year long-term measurement research, the service life of the NdFeB strong magnet can completely exceed 30 years, and its magnetic loss is very small even after 50 years. For exposed threaded holes, bolts, etc., as well as metal parts in the coating layer, special anti-corrosion treatment can be used, or stainless steel can be used to ensure its service life. Thereby ensuring the long service life of the entire product and meeting the product durability requirements in harsh environments.

We use TPV rubber to cover the Ndfeb magnets, Comparing with EPDM, NBR, TPV combines the features of vulcanized rubber with the processing properties of thermoplastics. The rubber has good processability, for which can be made in different sizes and shapes. Our rubberized magnet can be made in round shapes, oval shapes, rectangle shapes etc.

These rubber coated magnets are especially suitable for magnetically fixing objects such as work and advertising displays, attachments to cars body or other painted surfaces. For which thanks to TPV Rubber coating scratch-free performance. Strong pulling force with surface protection against scratching or marking.

It has almost perfect performance and characters of Strong pulling force, waterproof, durable, high traction, corrosion resistant, temperature resistant, magnets do not easily chip etc.

Long-term aging durability combined with dimensional stability and physical properties over the life of the part, also features good corrosion resistance and has good performance of rust protection.

Because the magnet inside the adhesive magnet sucker is completely protected by the rubber outside, isolated from the air and water, so even if long-term use, the magnet will not corrosion, so that the magnetic adsorption function can be maintained for a long time.

The rubber material coated on the surface of the rubber-coated magnet has good physical and chemical properties. We have different grades to choose from, some have very good UV resistance, some have very good oil resistance, some It has outstanding environmental resistance, etc., and by adding different trace components, it can also make the rubber achieve other different characteristics.

Because the magnet inside the adhesive magnet is completely protected by the rubber outside, the magnetic adsorption function can be maintained for a long time. The highest working temperature of the adhesive magnet can reach 80 degrees Celsius, and the lowest working temperature can reach -40 degrees Celsius, which can meet most of the use scenarios. extremely hot or cold will not affect their properties.

TPV rubber provides excellent performance for demanding consumer products applications and has become the global standard for engineering thermoplastic vulcanized elastomers. Rubber coating Materials are recyclable and environmental Friendly.

We are ISO 9001:2015 certified, and all our material quality control and production processes strictly in accordance with ISO requests. We are not only test magnetic force but also rubber tenacity. For which rubber material has High tenacity & Deformation resistance.

Our rubber covered magnets now are available in black, white, red , bule and yellow colors. We can also customize different colors according to customer needs,Welcome to contact us.

Tube MagnetOctober 15, 2021Product DescriptionThis is a perfect choice when positioning pipes, tubes in precast parts. Magnet produces great holding power so that it can be easily positioned at required spot of the mold.Item No...view

Tube MagnetOctober 15, 2021Product DescriptionThis is a perfect choice when positioning pipes, tubes in precast parts. Magnet produces great holding power so that it can be easily positioned at required spot of the mold.Item No...view Magnetic Base with L ArmApril 21, 2020This magnetic sign holder with L-shaped aluminum tube and 2 hooks. It can be attached to steel surfaces easily.view

Magnetic Base with L ArmApril 21, 2020This magnetic sign holder with L-shaped aluminum tube and 2 hooks. It can be attached to steel surfaces easily.view Oval Shape NdfeB Pot MagnetApril 21, 2020It is a very special part, more challenging than round-shape pot magnets in magnetic circuit design and we successfully secured the magnetic force at its requested size.view

Oval Shape NdfeB Pot MagnetApril 21, 2020It is a very special part, more challenging than round-shape pot magnets in magnetic circuit design and we successfully secured the magnetic force at its requested size.view Call us on:

Call us on:  Email Us:

Email Us:  No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China

No.808 BLD#4, Zhongxin Plaza, 99 Shangwu Blvd, Huaqiao, Kunshan Jiangsu Province 215332 China